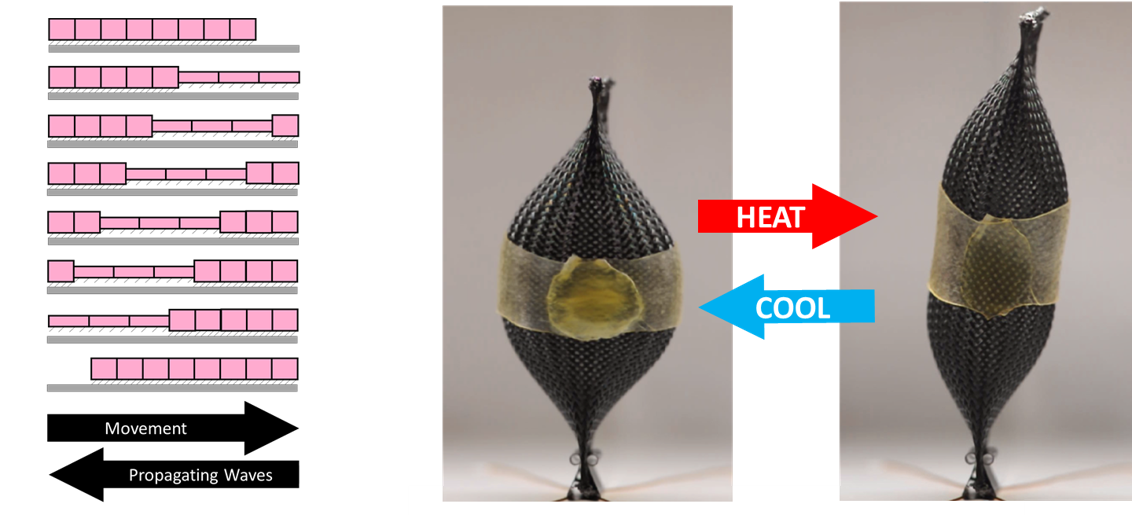

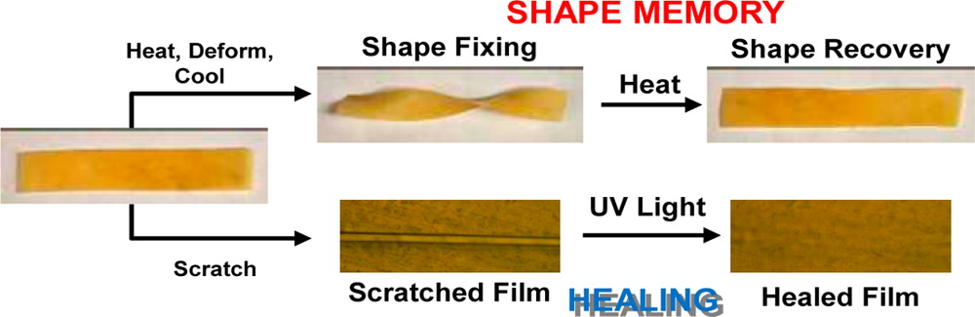

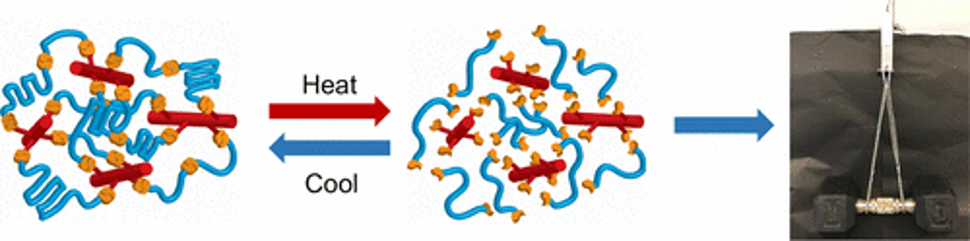

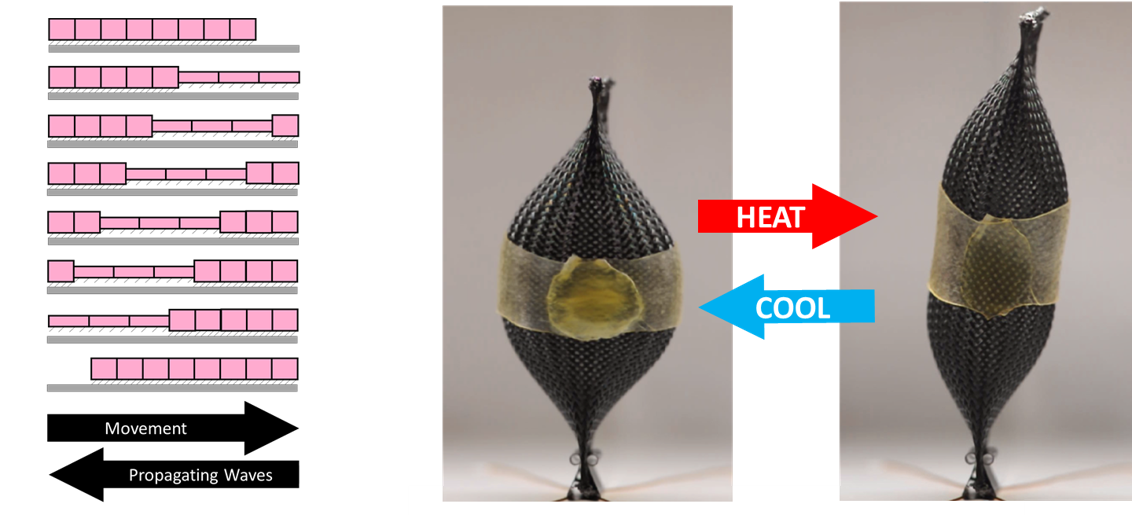

Another avenue of research pursued in the field of covalent structurally dynamic polymers by the Rowan group is their development as artificial muscles in soft robotics applications. Just as 3D printing, a technology originally based in chemistry and materials science, has been adapted to the field of robotics for the fabrication of passive structural elements, more recently, shape memory materials have started to be developed as active components to afford movement in soft robots. These materials serve as lighter and more easily miniaturized alternatives to the electric motors that roboticists traditionally use which are limited in their rigidity and achievable scale-down size.

As a part of an international collaboration with groups at Case Western Reserve University and the University of Fribourg in Switzerland, the Rowan group is currently working to design and synthesize crosslinked shape memory materials that incorporate dynamic bonds to function as artificial muscles in soft wormlike robots. Specifically, the development of these materials aims to enable the fabrication of soft robotic actuators in a variety of shapes and sizes without sacrificing the actuation properties of the base material.